A new report by the McKinsey Global Institute (MGI), “A Blueprint for Addressing the Global Affordable Housing Challenge,” defines the affordability gap as the difference between the cost of an acceptable standard housing unit (which varies by location) and what households can afford to pay using no more than 30 percent of income.

The analysis uses MGI’s Cityscope database of 2,400 metropolitan areas, as well as case studies from around the world.

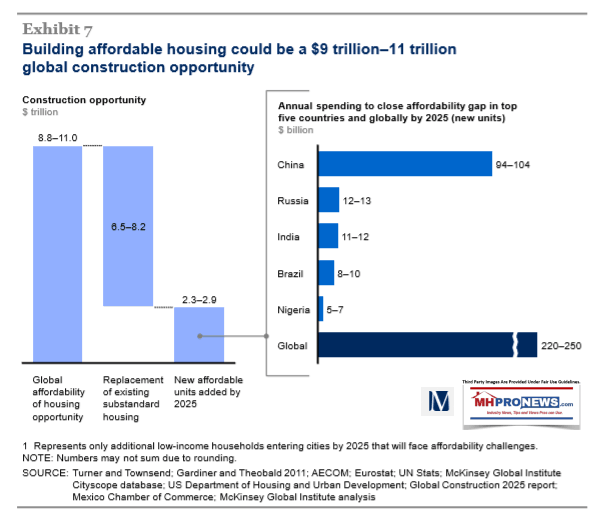

Per MGI, “It [the report] finds that the affordable housing gap now stands at $650 billion a year and that the problem will only grow as urban populations expand: current trends suggest that there could be 106 million more low-income urban households by 2025, for example. To replace today’s inadequate housing and build the additional units needed by 2025 would require $9 trillion to $11 trillion in construction spending alone. With land, the total cost could be $16 trillion. Of this, we estimate that $1 trillion to $3 trillion may have to come from public funding.”

Tens of millions are impacted here in the U.S., said MGI.

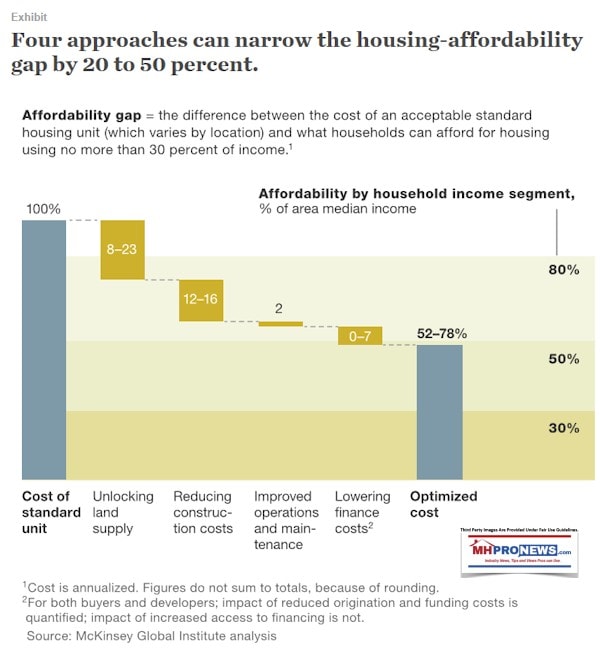

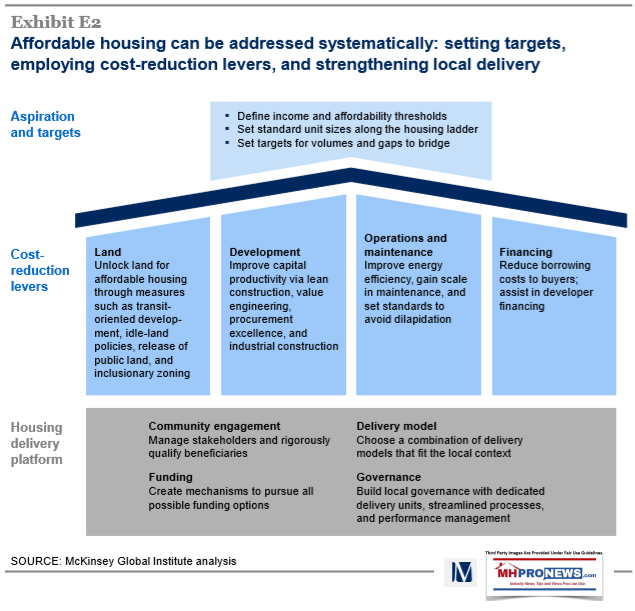

The propose a four-part plan to educe those costs.

Those 4 items are:

- Unlocking land supply.

- Reducing construction costs. “While manufacturing and other industries have raised productivity steadily in the past few decades, in construction it has remained flat or gone down in many countries. Likewise, in many places residential housing is still built in the same way it was 50 years ago. Project costs could be reduced by about 30 percent and completion schedules shortened by about 40 percent if developers make use of value engineering (standardizing design) and industrial approaches, such as assembling buildings from prefabricated components manufactured off-site. Efficient procurement methods and other process improvements would help, as well.” (Italics added).

- Improved operations and maintenance.

- Lowering financing costs for buyers and developers.

The video below is a summary of their research.

MH Industry Reaction

“The McKinsey research summary video says tens of millions of Americans can benefit from affordable housing near areas it’s needed. While they don’t specifically mention manufactured homes, they do say that engineered, industrialized homes with affordable lending in the right locales are among the keys needed,” said Mark Weiss, JD, President and CEO for the Manufactured Housing Association for Regulatory Reform (MHARR).

“That describes what MHARR has promoted for years; the full implementation of the Manufactured Housing Improvement Act of 2000,” said Weiss in a statement to the Daily Business News, “including enhanced preemption. Combined with FHA lending and the robust implementation of the Duty to Serve (DTS) by the Government Sponsored Enterprises (GSEs).”

The McKinsey research certainly includes various forms of prefab and modular housing.

But what many researchers may not realize is that a robust application of the MHIA 2000, the robust application of the GSEs DTS and a broader use of FHA Title I and Title II lending – all existing laws, that only need to be properly enforced and administered – could speed the time to addressing these issues.

The trillions of dollars in market potential globally provide a context for award-winning retailer, Alan Amy’s comments, below.

It is the latest example of what MHLivingNews reported some years ago. Namely, that the “Solution to the Affordable Housing Crisis is Hiding in Plain Sight.” Research has suggested that manufactured homes are not only less costly to buy, they are also less costly to maintain.

The clock has been ticking since this report was first issued. While several types of factory-built housing could be used, shouldn’t the watchwords be, let’s get started? ## (News, analysis, and commentary.)

(Third party images, and cites are provided under fair use guidelines.)

1) To sign up in seconds for our MH Industry leading emailed news updates, click here.

2) To provide a News Tips and/or Commentary, click the link to the left. Please note if comments are on-or-off the record, thank you.

3) Marketing, Web, Video, Consulting, Recruiting and Training Resources

Soheyla is a managing member of LifeStyle Factory Homes, LLC, the parent company to MHProNews, and MHLivingNews.com.